|

lick pictures for a larger version.

BFR rear sight is fully adjustable for windage &

elevation.

Front sight is custom fabricated by Ryan Ross.

Top of frame is drilled & tapped for scope mount.

|

|

Ryan

Ross of Ross Custom Arms in Hickory Grove, SC, is quickly

gaining a reputation as one of America's top custom revolver

makers. He was mentored by the late, great John Gallagher, has

cut his teeth on many custom projects, and is now taking his

business in a new direction.

I

first became aware of Ryan's work after I received what was to

have been my dear departed friend Terry

Murbach's last custom revolver: a

custom five-shot center-fire conversion of a Ruger® Old Model

Single-Six® in 380 ACP (or 9mm Kurz, as Terry preferred to

call it). My brother Shootist

and great friend Fermin

Garza clued me in that Ryan Ross actually did the barrel

work on that project, and made an introduction between me and

Ryan. Since that time, over countless phone and text conversations

and a pleasant afternoon of shooting (both custom revolvers and

The Breeze) here at my place, Ryan and I have become good

friends. I always look forward to our conversations, as they are

always instructive and indicative of Ryan's well-reasoned

philosophies on custom guns, and on life in general.

The

new direction Ryan has taken with his business is that, while

most custom revolver makers base their offerings on Ruger

sixguns, Ryan focuses his Single-Action revolver work on the Magnum

Research® BFR

("Biggest, Finest Revolver"). Ruger's

Single-Actions, at their introduction, revolutionized the

sixgun, and the quality that Ruger still offers for the price is

phenomenal. Thanks to the influence of gun writers such as

Skeeter Skelton and John Taffin, countless

Ruger "medium-frame" Old Model 357 Magnum sixguns have

been converted to fire the wonderful 44 Special cartridge,

to the point that Ruger now produces the

"medium-frame" New Model Blackhawk in 44 Special as

Distributor's Exclusives. Ruger's "full-size"

Blackhawks, especially the Bisley model, have become the

platform for five-shot big-bore revolvers capable of taking any

game on Planet Earth, and several

of America's top revolver smiths offer such revolvers based on

the large-frame Ruger Single-Action. I own several of these

big-bore Ruger conversions, from makers such as Hamilton Bowen,

the late John Linebaugh, and Dustin Linebaugh, and I can attest

that these are among the finest revolvers available anywhere, at

any price.

So,

why would Ryan Ross choose to specialize in the Magnum Research

BFR instead of the Ruger?

When

I discussed with Ryan his reasoning behind working from the BFR

platform rather than the Ruger, I was treated to a half-hour

lecture detailing why the BFR is a better custom-gun platform.

We have reviewed several big-bore Magnum Research BFR revolvers

in the past, including their Custom

Shop "No. 5" in 500 Linebaugh, their BFR

Bisley 500 Linebaugh, their 475

Linebaugh / 480 Ruger Bisley model, and their BFR

50 Beowulf, so I am well aware of the BFR's quality. While

Ruger offers a great sixgun at a great price, the BFR is

significantly better in many respects, with noticeably better

fit and finish, tighter lockup, and better actions, while

retailing for only a few hundred dollars more than the Ruger.

Even more important from the perspective of a custom gun maker,

the BFR's cylinder, and thus the frame's cylinder window, is

larger than the Ruger's; this means that larger cylinders can be

used in the BFR without the extra work (and extra labor cost) of

opening up the Ruger frame's cylinder window (and thereby

arguably weakening the Ruger's legendarily-strong frame). Also,

because Magnum Research takes greater pains in manufacturing,

there is less remedial metal work to be done; in fairness to

Ruger (and I am definitely a "Ruger Guy"), this allows

Ruger to offer their revolvers at a price most shooters can

afford, and the greater pains taken by Magnum Research is why

their offerings typically cost $300-400 more than the Ruger.

Working from the BFR as a starting point is very wise from a

practical perspective, and it has the further advantage of

setting Ross Custom Arms apart from other custom gun makers.

This

particular Magnum Research BFR started life as a six-shot 44

Magnum. As previously stated, the BFR's cylinder is larger in

diameter than the Ruger's, which leaves plenty of steel between

the chambers and around the cylinder's periphery to allow six

shots of the heaviest 45 Colt loads to be fired safely. The

additional length of the BFR cylinder over the Ruger also allows

the heavier 325-grain to 360-grain specialty factory loadings to

be used. Beginning with the cylinder, Ryan line-indexed and

rechambered the 44 Magnum cylinder to a tight 45 Colt, with

chamber throats sized to an optimal 0.4525". Line-indexing

perfectly aligns the chambers with the bore, so that there is no

deflection or deformation of the bullet as it travels from the

cylinder into the barrel's forcing cone and out the barrel. This

deflection / deformation caused by misalignment is a major cause

of inaccuracy in revolvers, and Ryan has eliminated this

possibility from the equation. The rear of the cylinder is cut

for recessed case heads, which not only looks nice but, more

importantly, fully supports the case heads when using the

heaviest of loads.

The

factory barrel is replaced by a 5.5-inch unit, fabricated by

Ryan Ross from Douglas XX barrel stock, rifled at a 1:16"

twist to allow heavier bullets to stabilize for longer-range

accuracy. The muzzle is "stepped" as seen on Elmer

Keith's famous #5 sixgun, and the crown is cut in the manner

found on custom precision rifles, with zero run-out; the forcing

cone is cut with this same zero run-out philosophy, resulting in

absolute concentricity with the cylinder for maximum accuracy.

Finally, the barrel is set to achieve a barrel / cylinder gap of

0.0015" - PERFECT.

Ryan's

action work includes the requisite stoning / polishing to

achieve smoothness as would be expected. He utilizes an

increased-power hammer spring to assure reliable ignition of the

hardest primers, coupled with a reduced-power trigger spring to

lighten trigger pull. Speaking of which, the trigger pull was

absolutely amazing, very crisply and cleanly letting-off at just

1.5 pounds; even at such a light weight, the trigger still felt

very "solid", so much so that I felt the need to

verify my pull measurement using a second gauge, and there is

nothing unsafe about the trigger feel. Ryan was as surprised as

I was about the lightness of the measured pull, as he doesn't

own a trigger pull gauge; he learned from John Gallagher to set

the trigger to a certain "feel", and Gallagher never

worried about what the pull measured, as long as the action

itself was light and safe. To aid in this, Ryan cuts an extra

notch into the hammer and trigger to allow for more positive

engagement, so that a lighter and crisper trigger pull weight

can be achieved without sacrificing safety.

Properly

timing a sixgun is not just a craft, but an ART, and Ryan excels

at it. He corrects any minor timing issues inherent to the base

revolver, corrects any end shake, and installs an oversized

locking bolt, resulting in a tight and positive action with zero

movement allowed. The oversized locking bolt drops

perfectly into its cylinder slot precisely when the hammer

reaches its rearward position. This sixgun locks up like the

proverbial bank vault, with no discernible movement, either

laterally or fore/aft.

Precision

fitting of a properly-timed cylinder doesn't account for much

without a properly-fitted cylinder base pin, and this is a

component overlooked by many shooters. Ryan hand-fits an

oversized #5-style base pin, with an oversized set screw. The

set screw prevents the base pin from moving forward or flying

out under recoil, which can result in anything from a minor

inconvenience to a violent death by hoof and horn, depending on

the situation. Since the BFR does not include a cross-pin base

pin latch, the set screw takes the brunt of these shear forces;

Ryan uses an oversized set screw for this purpose, and firmly

anchors it into the bottom of the barrel. The #5-style

step-tapered head allows the base pin to be firmly grasped, as

it takes a bit more force to remove the oversized pin once the

set screw is removed.

The

excellent BFR adjustable rear sight is retained, as there is not

really a way to improve upon it; this rear sight is fully adjustable

for windage and elevation, is rugged and reliable, and features

a serrated and angled rear blade that extends over the hammer,

allowing a greater sight radius and glare-free operation. The

front sight is REALLY cool, and again reminiscent of Elmer

Keith's famed #5. Ryan fabricates a 17-4 Stainless base that is

precisely radiused on the bottom to mate with the barrel; into

this base, Ryan attaches his front blade with two pins, instead

of the commonly-encountered single pin, for increased stability.

The blade itself is blued steel, and stepped to allow multiple

aiming points for precise shooting at various ranges, making it

effective out to a good 800-1000 yards. Finally, if one wishes

to mount an optical sight, the BFR's top strap is drilled and

tapped for a scope mount.

As

mentioned above, Magnum Research puts a lot of effort into

assuring that all metal work is straight and true, but there is

a limit to which any manufacturer must adhere in order to keep

prices in line. To put the BFR over the top as a

"Best-Quality" sixgun, Ryan does quite a bit of

remedial metal work; he spends a good deal of time assuring that

all lines are straight and true, all radii are precise, and all

angles are sharply defined. Ryan draw-files the frame sides

flat, and hand-cards (blends) the cylinder (main) frame to the

grip frame so that the line between them can barely be seen, and

not at all felt. As a final aesthetic touch, Ryan slots the

action pins on the port side, so that they give the appearance

of traditional screws. Such attention to detail is what gives a

custom revolver the look of a Custom Revolver, and sets it apart

from any factory-made piece.

The

BFR's grip frame is reminiscent of Ruger's

Super Blackhawk shape, without the squared Dragoon trigger

guard, but is dimensionally unique, with a bit more drop-down

and a bit more canted angle. The grips are American Walnut

(a.k.a. Eastern Black Walnut), nicely figured, and superbly fit

and finished using Tung Oil in the old Winchester style,

yielding a very classy and beautiful appearance. The grip

profile is a bit thicker than most, but not so thick as to make

the grip uncomfortable. The extra bit of grip width will be

welcome to the shooter who uses full-power Magnum-level loads,

as the recoil force is spread out over a larger area of the

palm. As a result, shooting the Ross Custom Arms BFR 45 was a

joy, with even the hardest-hitting loads being memorable, but

not painful.

Build Sheet - Ross

Custom Arms BFR 45 Colt Six-Shot Custom Conversion

| Action

Job |

| Timing

correction |

| Trigger

and Hammer Modification |

| Oversized

Locking Bolt |

| Increased

Power Hammer Spring |

| Reduced

Power Trigger Spring |

| End

Shake Fix |

| Oversized

Locking Base Pin #5 Style |

| Tight

Chamber 45 Colt |

| 0.4525"

Throats |

| Douglas

XX Barrel 5.5", Keith No 5 style muzzle |

|

17-4

Sight Base, Precisely Machined to Barrel Contour, 2-Pin

Style for Added Rigidity |

| Set

Barrel / Cylinder Gap 0.0015" |

| Considerable

Metal Remediation |

| Draw-File

Frame Sides Flat |

| Hand

Carded (Blended) |

| Slot

Hammer and Trigger Pin |

|

American

Walnut aka Eastern Black grips - Handcrafted and fit to

gun, Tung

oil Finished in the Old Winchester Style |

| Price (as tested): $2,500.00 on

Customer-Supplied Base Gun |

As

for pricing, custom sixguns are just that - CUSTOM - so final

price will be set depending upon the buyer's individual desires.

To have Ryan Ross build a custom sixgun like this one, with all

the bells and whistles, would cost about $2,500.00, as of this

date, on the customer's base BFR. To get a version with all the

basic work (tight re-chamber, new barrel, all action work),

using a modified BFR sight base with a blade contoured as on

this example, but without the extra metal prep and custom grips,

would cost about $1,600.00 on the customer's base BFR. If you

have done any comparison shopping or buying of custom revolvers,

then you know that these prices are quite reasonable. Ryan Ross

is doing some fine custom work, on both on the Magnum Research

BFR Single-Action and the Ruger Redhawk Double-Action...more on

that to come!...and I predict he will be famous, back-logged,

and charging higher prices soon.

Certainly,

Ross Custom Guns' work is not cheap - but the Best never

is.

Check

out Ryan Ross' work at:

www.rosscustomarms.com

(Web Site Currently UNDER CONSTRUCTION)

Magnum

Research®:

www.magnumresearch.com

www.magnumresearch.com/bfr-biggest-finest-revolver/

Order

Ammo Online at Lucky Gunner:

www.luckygunner.com

Fermin

C Garza's Customized Shooter's Resources:

www.fermincgarza.com

Fiocchi®

Ammunition:

www.fiocchiusa.com

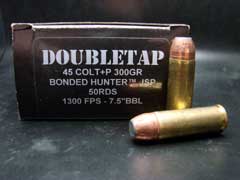

Double

Tap Ammunition:

www.doubletapammo.com

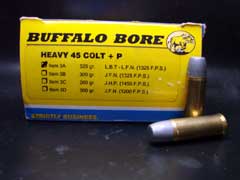

Buffalo

Bore Ammunition:

www.buffalobore.com

ConcealedCarry.com

Digital Trigger Pull Gauge: www.concealedcarry.com/product/digital-trigger-pull-gauge/

Boge Quinn

Got something to say about this article?

Want to agree (or disagree) with it? Click the following link to

go to the GUNBlast Feedback Page.

|

|

Click pictures for a larger version.

Action pins are slotted on the port side to resemble

screws.

6-Shot group @ 50 yards, benchrested.

6-Shot group @ 50 yards, benchrested.

|

![]()