|

Click pictures for a larger version.

The "Silk Purse"

|

|

Sometime in the latter part of the last

decade of the last century, fellow Shootist

Jim Taylor wrote an article entitled “Turning a Sow’s Ear

into a Silk Purse”, whereby he turned a rough, shooter grade,

Ruger old model Blackhawk in 357 Mag, with a 6.5” barrel, into

a wonderful, compact, finely refinished sixgun.

He described the process from the base gun, with all its

“character”, walked the reader through the process of the

project, and finished with the end product.

This is a throw back to that article, with a slightly

more modern twist: a double action twist.

Back in late 2019, I wrote an article about

the Gunsite 250R revolver

project.

This was a set of 15 custom S&W model 10 revolvers

with a 3” barrel. I described the genesis of the project, the craftsmen

involved in building them, and the resulting product.

I’d have to get the webmaster’s count on the number

of views, or reads, but I’d like to think that this article,

along with a growing resurgence, nationally, of the double

action revolver, has been instrumental in the significant demand

for the base guns, barrels, and parts that were once plentiful

and are now non-existent. The

base guns, barrel-less S&W model 10s imported at first from

Malaysia, and now from South America, are getting rather scarce,

especially decent condition ones.

The 3” heavy barrels that were once plentiful from

on-line parts stores are now completely dried up, and the center

pins and cylinder rods are quite challenging to find as well.

While perusing one of the more popular

on-line gun auction websites, I came across what was described

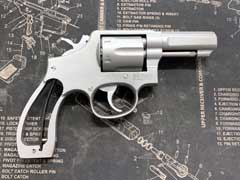

as a “S&W 64 - Needs Work”.

The S&W 64, introduced in 1974, is a stainless steel,

K-frame, fixed sight, 6-shot, single/double action revolver with

either a round or square butt, and either a 2” or 4” barrel.

It was the second all-stainless-steel revolver introduced

by S&W, after the model 60. It quickly became a favorite of police, sheriff, security,

and State agencies and was widely used for many years. In fact, some of these are still showing up today in police

surplus stores, indicating that some are either still in use, or

these agencies are finally clearing out their armories!

Back to this “Needs Work” gun…looking at the

pictures, it showed the usual surplus wear marks, light dings,

scratches and marks of a duty gun.

I could tell from one of the pictures that the cylinder

stop screw was missing, but nothing else was obvious.

Assuming the “needs work” was related to the

internals and action, I decided to go ahead and take a chance on

it and buy it. A

week or so later, having the gun in hand, I was able to examine

it. The pictures

pretty much did it justice, except for the missing cylinder stop

screw. It was sort

of missing…the screw head had been sheared off and the screw

was still in the frame. I

took the gun to Nelson Ford, The

Gunsmith, here in Phoenix, AZ

and had him inspect the gun to determine what “needed work”.

After a very thorough exam, he could find nothing wrong

with the gun, and handed me a pair of needle nose pliers to

manually unscrew the sheared off cylinder stop screw, which was

completed in a matter of a few minutes, and a replacement screw

found in one of Nelson’s many parts bins, was installed.

I now had a fully functional, though cosmetically

challenged, Model 64.

My brain started cogitating on what to do

with that gun, and David Fink’s recent words to me about his

on-going challenges in finding barrels, center pins, and

cylinder rods for the Gunsite 250R projects that have been

coming in to him in droves, led me to wonder why I couldn’t

use this gun as a base gun for a 250R of sorts.

It would be stainless, instead of blue, and the original

4” heavy barrel would need to be cut, instead of needing to

find a barrel for the barrel-less base guns.

It only took me a few days to decide on this venture, and

off I was.

I took the gun to Fink’s Custom

Gunsmithing, now, since April 2021, the Gunsmithy at Gunsite,

and asked him to perform the following work: 1) cut barrel to

3”, 2) crown barrel, 3) slab-side barrel (because not only

does it remove the off-center factory barrel stampings after the

barrel shortening, but I like the looks of it), 4) round butt

the gun, and 5) satin bead blast the gun.

I intentionally did not have a front sight installed on

the gun, or have an action job done, as I had other plans for

both of those. After

what seemed like an eternity, but in reality was a rather

respectable turn-around time of a few weeks, I picked up the gun

back up from Fink’s.

It was exactly as I had asked for it to be and even

better, as the fine craftsmen at Fink’s decided that they

should clean up some of the marks and gouges from who knows how

many years of police/security holster carry.

It was well on its way to being a fine sixgun!

Back in November, while on a long weekend

trip back to Pennsylvania for a home Penn State football game, I

took the opportunity to spend a day and visit with my friend

Wayne Novak at his shop in Parkersburg, WV.

While I was there, he and Charlie, the President there at

Novak’s, showed me some of the work that they had been doing

with revolver sights, both front and rear.

They had already been supplying these for the Ruger Wiley

Clapp revolvers, both GP-100 and SP-101, but also showed me some

work they had been prototyping on S&W revolvers.

I called Wayne and asked him if he would/could install a

set of his sights on this gun, with a gold bead front sight a

must. Wayne sold me

on the gold bead fronts sight about 10 years ago, during one of

my first visits at his shop.

The gold really reflects light and, even in the dark,

when shooting with a flashlight, either in hand or weapon

mounted, superbly works at reflecting light for a quick front

sight acquisition. His

reply to me was “send it”.

So off to Parkersburg the gun went.

After a week or so, Wayne contacted me and explained that

the top strop on this gun was a little too thin for them to

comfortably cut their dovetail for their rear sight. He recommended we leave the factory fixed rear sight but

proceed with one of his trademark gold bead domed rear sights.

Wayne indicated that this is the exact sight set up that

he uses for his personal revolvers. Trusting the expert’s advice is a trait my father taught me

early on, so the sights were quickly decided and agreed upon.

Titus Williams, one of the fine craftsmen there at

Novak’s, promptly cut the dovetail in the barrel and installed

the gold bead front sight and, in very short order, the gun was

on its way back to Phoenix.

FedEx shipping delays not withstanding, it was back in my

hands about 10 days later, and boy that gold bead sure does pop

in the Arizona daylight!

Last came the action job.

One of the things I have learned from another expert,

Nelson Ford, was to always wait until everything else is done on

a gun before doing the action.

This ensure that nothing interferes with the precise

tuning of the gun during the action work.

All, or any, finish work, sight work, barrel setting,

etc… can affect the action tune.

This gun was now ready for some of Nelson’s wizardry.

I left the gun with him, paid him for the action work,

and waited. He

specializes in S&W revolvers, Colt revolvers, 1911s, and

Browning Hi Powers, but can also do quite impressive work on

Marlin and Winchester rifles.

It’s actually quite surprising that his turnaround time

is only 6 weeks or so. Trust

me, it is well worth the wait.

He is a master at tuning these guns.

The K-frame especially lends itself to some amazing

results. While

I’ve had him to work on S&W J-frames, K/L frames and N

frames, the K frames guns really turn out amazingly well.

He finished the work and, after test firing it (he

personally test fires every gun he works on), turned it back

over to me. Wow,

what an impressive difference from the factory action.

I have learned from him that a proper action tuning is

more than just adjusting the hammer spring.

It involves ensuring the cylinder is set correctly not

only for optimal barrel/cylinder gap but also for the recoil

shield (so cartridges don’t drag on the recoil shield or

firing pin bushing), that the cylinder release latch is properly

tuned for ease of cylinder opening and closing, that the firing

pin is spring loaded so that it provides consistent, repeatable

strikes on the primers, thus allowing for backing off of the

hammer spring tension, that all the internal parts are polished

and aligned for optimal alignment, and that the trigger is

polished smooth for optimal double action work.

There is quite a lot of work into a proper action tuning

on a double action revolver, and Nelson Ford is one of the best

in the country. Having

been in the same location for 42 years, he has developed a very

wide and solid customer base.

For now, I decided to install a set of VZ

grips on the gun. These

particular ones are designed for the round butt S&W K-frame

and fit perfectly. While some G10 grips can have rather quite aggressive

checkering, these are on the medium side of my subjective

“grip aggressiveness” scale and feel just right.

The only modification I made on them was to remove the

finger grooves as I have rather large hands and finger grooves

almost never fit my hand correctly resulting in a poor grip from

the holster. While

this may be a minor inconvenience at the range, on the street,

where time will be of the essence, I can’t take the chance of

a poor grip. The grip is the first, and quite critical, part of the

presentation, and I need every advantage I can get, so want to

avoid any interference with my large hands.

I remember a rather tall fellow, with large hands, from

Louisiana that spent a career in the Border Patrol before his

retirement in trick shooting and fast draw, who was a big

proponent of large, smooth grips with no finger grooves.

He might have talked about that in one of his books, No

Second Place Winner, back almost 60 years ago.

His name was Bill Jordan.

It worked for him then, and it works for me now, albeit

with a slight G10 twist from VZ.

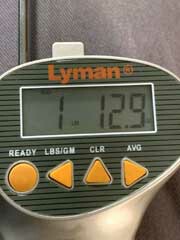

Now came the time for the best part, actually

firing the gun! Double

action work was absolutely enjoyable with this gun, with a

smooth, steady and consistent double action pull of barely over

five pounds.

The single action let off was also quite pleasant at 1

pound, 13 ounces. With my

handloads with a 158-gr lead semi wadcutter bullet, the sights

were dead on for both elevation and windage, a testament to

Titus’ fine work at Novak’s.

Groups were very adequate for the gun’s self-defense

intended purpose. This

sixgun has become a very reliable, trusted, and depended-upon

tool that I hope will be on my right hip for many years to come.

It is a sixgun that that not only functions perfectly,

but also looks great, and is a tribute to “turning a sow’s

ear into a silk purse”.

Thank

you, Jim Taylor, for the inspiration some 25 years ago!

Matt

Olivier

Got something to say about this article?

Want to agree (or disagree) with it? Click the following link to

go to the GUNBlast Feedback Page.

|

|

Click pictures for a larger version.

The "Sow's Ear"

"In-Progress"

|

![]()