|

It has been almost two months since I reviewed

the new Ruger SP101 chambered

for the .327 Federal Magnum cartridge. The little Ruger

revolver was the first handgun to chamber the new cartridge, and

it is intended and marketed as a defensive cartridge for those

who want deep penetration and expansion, without the recoil and

muzzle blast of the .357 Magnum cartridge. In that role, the

little SP101 performs admirably.

Like many shooters, I have been anxiously

awaiting the arrival of hunting revolvers chambered for the new

cartridge. Freedom Arms in Freedom, Wyoming got on the

project right away, and they are now offering their .32

H&R Magnum Model 97 with an optional .327 Federal

Magnum cylinder, and Freedom will also fit a .327 Federal

cylinder to existing .32 H&R Freedom revolvers.

The Freedom revolver tested here wears a five

and one-half inch barrel, and I was anxious to see what that

extra barrel length and tighter barrel/cylinder gap of just .002

inch would do for velocities, compared to the smaller Ruger with

its three and one-sixteenth inch barrel. The quality of

materials and workmanship on Freedom Arms revolvers is

legendary, so coupled with the longer barrel and target style

rear sight, I also expected better accuracy. The cylinder length

of the Model 97 .327 Federal Magnum measures 1.628, and the

cartridge case heads are recessed into the cylinder, allowing

the use of cartridges loaded to just under the total cylinder

length. The cylinder diameter measures 1.575 inches, and

contains six chambers. The Model 97 weighs 41.4 ounces unloaded,

and has an excellent trigger pull, measuring just two and

three-quarters pounds. This Model 97 wears the exceptional

Freedom Arms fully adjustable rear sight, and has a black ramped

front. The majority of the sixgun is made of stainless steel,

and wears Freedom’s Premier Grade finish, and their perfectly

fitted wood grips.

About two weeks into shooting the new Model 97,

I received a custom Ruger Single Six from Alan

Harton’s Single Action Service, so I decided to review

them both in one article, as they are both intended to be used

as hunting and target shooting guns. The custom Ruger wears a

six and one-half inch barrel, and also has a tight

barrel/cylinder gap of just .003 inch. The standard .32 H&R

Single Six cylinder is too short for the .327 Federal, so a

longer cylinder was fitted, which required slightly shortening

the part of the barrel that protrudes into the cylinder window

of the Single Six. Mr. Harton fitted a new barrel to the frame,

and installed a free-spin pawl that allows the cylinder to

freely spin in either direction when the loading gate is open.

The cylinder length on the custom Ruger is 1.538 inches, and the

case heads are not recessed, allowing for a total overall

cartridge length of 1.581 inches. The cylinder diameter measures

1.462 inches, and the custom Ruger is also chambered to hold six

rounds of .327 Federal Magnum ammunition. The custom Ruger

weighs 38 ounces unloaded. The trigger pull measured a clean,

crisp one pound, fifteen ounces. The Harton custom wears an

excellent adjustable rear sight, and a ramped front. Being a

custom sixgun, barrel lengths, finishes, sights, and grips are

all done to the customer’s specifications.

This review is in no way intended to compare the

Freedom Arms revolver with the Harton custom Ruger. They are

each just two different approaches to achieve the same result.

That is, a high quality hunting and target sixgun chambered for

the .327 Federal Cartridge. The .327 Federal is all that we

hoped that the .32 H&R would be when introduced many years

ago. The pressures on the H&R cartridge were limited by what

the .32 Harrington & Richardson guns could handle.

For years, shooters have been loading the .32 H&R in Ruger

revolvers to true magnum pressures, but with the introduction of

the .327 Federal, the case length is increased, increasing

powder capacity and allowing higher velocities. As far as I

know, there is yet no published pressure tested load data

available, so when loading for the two single action revolvers

reviewed here, I was on my own. Benefiting from my handloading

notes from the review of the SP101, I had a good place to start.

I made a couple of mistakes loading the little Ruger, so I did

not try to push the velocities over safe limits here, but

carefully watch for fired primer condition, ease of extraction,

and measured case head expansion in developing handloads for

these two sixguns. The loads listed here have not been pressure

tested, but proved safe in the two revolvers. If loading the

.327, start with lower powder charges, and pay careful attention

to pressure signs. If extraction gets sticky, back off a bit.

Hopefully, we will soon have good load data from a reliable

source available. The handloads listed here were all loaded on a

Dillon 550B machine using Lee

.32 H&R dies, and all used CCI 550 Magnum Small

Pistol primers. Unless otherwise noted, all bullets were

roll-crimped at their crimp groove or cannelure. The sixty grain

XTP has no cannelure, and was roll-crimped at the start of the

ogive. The loads using the Mt. Baldy

bullets that are noted as “ long” were crimped into the

upper grease groove to increase case capacity. I found no

advantage to seating the bullets long, as I achieved higher

velocities using less powder crimping those bullets in the crimp

groove, but it was worth trying. You can achieve roughly the

same velocities with less pressure by seating them long, but

with the powders chosen here, I prefer to seat the bullets

normally. During velocity testing, the air temperature was

between 42 and 47 degrees Fahrenheit, at an elevation of

approximately 400 feet above sea level. All loads were fired

over the electronic eyes of a PACT Professional

chronograph, and thankfully, it worked well throughout the

velocity tests. I believe that the chronograph was invented

mostly to add aggravation to the lives of gunwriters, but it

does come in handy for load development. Again, the loads listed

below worked well in the two revolvers tested here, but should

be reduced for any other firearm. I started low and worked up

from there. You can too.

I used three jacketed and four cast bullets in

the two revolvers. Many more loads were tested than those shown

here, but these represent the best of the bunch. From my earlier

experience loading the .327 Federal in the SP101, I chose Accurate

Number 9 and Hodgdon H110 as the powders to use in these

two revolvers. In almost every load, the powder charges were

compressed, some heavily. I have had good results with Lil’Gun,

but did not try it with these two revolvers, as I have heard

that Lil’Gun can accelerate forcing cone erosion, and until I

can do further testing to prove or disprove that, I will not use

it in guns that do not belong to me. Also, these two powders

used here will do anything that Lil’Gun will do in the .327

Federal Magnum cartridge. In the table below, XTP is a Hornady

controlled expansion jacketed hollowpoint bullet. The cast lead

bullets are all of LBT or semi-wadcutter shape, and all have

flat nose designs. CP is Cast

Performance Bullet Company. Mt. B is Mt. Baldy Bullet

Company. GC is a gas checked bullet. PB is a plain base cast

lead bullet. K is a cast bullet designed and cast by John

Killebrew, and he was kind enough to run off a batch for me.

He does not sell them. Bullet weights are listed in grains.

Velocity is listed in feet-per-second (fps). In the velocity

listings, FA is Freedom Arms Model 97 with a 5.5 inch barrel,

and SAS is the custom Single Action Service Ruger with a 6.5

inch barrel. I also had all three of the currently produced

factory loads available, and their velocities are included in

the table.

| Bullet |

Powder |

Charge Weight |

Velocity FA |

Velocity SAS |

| 100 XTP |

H110 |

16.5 |

1604.3 |

1707.7 |

| CP 113 GC |

H110 |

16.5 |

1658.8 |

1691 |

| Mt. B 120 GC LONG |

H110 |

16.5 |

1617.1 |

1641.8 |

| Mt. B 120 GC LONG |

AA#9 |

14.3 |

1602.7 |

1613.1 |

| K 135 PB |

H110 |

14.8 |

1579.3 |

1588.6 |

| 85 XTP |

H110 |

17 |

1726.7 |

1742 |

| 60 XTP |

AA#9 |

17.4 |

2142.1 |

2192.7 |

| Mt. B 120 GC |

AA#9 |

13 |

1643.4 |

1649.9 |

| 100 XTP |

AA#9 |

14 |

1692 |

1703.5 |

| CP 113 GC |

AA#9 |

14 |

1617.6 |

1752.4 |

| AE 100 Factory Load |

NA |

NA |

1579.9 |

1649.6 |

| Federal 85 Factory Load |

NA |

NA |

1552.4 |

1611.2 |

| Speer 115 Factory Load |

NA |

NA |

1462.6 |

1578.4 |

In handloading the .327 Federal, pay careful

attention to bullet design. The location of the crimp groove is

important. Depending upon the location of the groove, the powder

capacity is either increased or decreased. Just because a bullet

weighs the same as those listed here, does not mean that powder

charges will be the same.

Accuracy with both revolvers was excellent. I

clamped the Harton Custom Ruger into my Ransom

Master Rest, but had no insert for the Freedom Model 97,

so it was accuracy tested handheld over a solid rest. Both

revolvers proved accurate, but due to different testing methods,

cannot be realistically compared. That really is not important,

however, as both sixguns exhibited superb accuracy with favored

loads. Testing a wide variety of handloads for accuracy, most of

the largest groups fired were in the one and one-half inch range

at twenty-five yards. No group fired exceeded two inches, and

the best loads found for each gun are pictured here. Both

sixguns would group at or under one inch all day long with the

loads that it liked. With the worst loads tested, both revolvers

were still very accurate. I did not have enough factory

ammunition to test those for accuracy. Looking at the velocities

achieved with these two sixguns, I am even more impressed with

the little .327 Federal Magnum than I was when testing the

SP101. I am curious to see what the cartridge can do in even

longer barrels. A seven and one-half inch sixgun would still

carry well in a holster, and I know that Freedom Arms has

produced at least one Model 97 with a ten inch barrel. That gun

will be going to my friend John Taffin for review, so

look for it in either GUNS or AMERICAN HANDGUNNER

magazine soon. Hopefully, someone like Marlin will

produce a handy little carbine chambered for the .327 Federal

magnum cartridge.

For a closer look at the Freedom Arms Model 97,

along with price and options information, go to www.freedomarms.com.

To inquire about having a custom sixgun built by

Alan Harton, give him a call at 713-772-8314 or 713-907-603, or

send an email to aharton@hotmail.com.

For more information on the .327 Federal Magnum

cartridge, go to www.federalcartridge.com.

To order the bullets tested here, go to www.castperformance.com,

www.mtbaldybullets.com,

and www.hornady.com.

Jeff Quinn

|

Single Action Service custom Ruger (top);

Freedom Arms Model 97 (center); Ruger SP101 with Sack

Peterson custom American Elk grip inserts (bottom).

Factory loads tested.

In both sixguns, .312 bullets fit snugly

into the throats.

Bullets used in handloads (left to

right): 60-grain Hornady XTP, 85-grain Hornady XTP, 100-grain

Hornady XTP, 113-grain Cast Performance gas-check, 118-grain

Cast Performance plain-base, 120-grain Mt. Baldy gas-check,

135-grain Killibrew plain-base.

Ransom rest.

Both sixguns proved to be exceptionally

and consistently accurate.

|

NOTE: All load data posted on this

web site are for educational purposes only. Neither the author nor

GunBlast.com assume any responsibility for the use or misuse of this data.

The data indicated were arrived at using specialized equipment under

conditions not necessarily comparable to those encountered by the

potential user of this data. Always use data from respected loading

manuals and begin working up loads at least 10% below the loads indicated

in the source manual.

Got something to say about this article? Want to agree (or

disagree) with it? Click the following link to go to the GUNBlast Feedback Page.

|

|

Click pictures for a larger version.

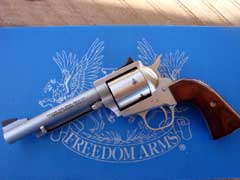

Single Action Service custom Ruger (top), Freedom Arms

Model 97 (bottom).

Freedom Arms Model 97.

Single Action Service custom Ruger.

|

![]()