|

Click pictures for a larger version.

A pair of RW aluminum Bisley grip frames. Shown here with the optional

micarta stocks. Plenty of material for precise fitting to the individual hand.

By using common locator holes Ronnie Wells can alter front and back

straps, change the grip angle, and lengthen or shorten his grip frames. Shown

here a Bradshaw with a standard Bisley in brass.

The Game Changer himself checking grip frame fit.

An aluminum Bisley grip frame on a Ruger OM Blackhawk.

Note the added material on the sides so this grip frame can also

fit the longer Ruger Maximum model.

RW Gripframes bring quality equal to the finest custom sixguns today. Here

on a OM Flattop with an extended top strap and fine walnut stocks.

A trip back in time. An 1860 grip frame in brass on a NM Super Blackhawk.

Ready to ride with Josey Wales.

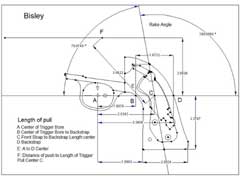

The Ruger Bisley Grip frame mapped out. Length of Pull for a sixgun is

calculated as well as the frame angles which can be manipulated to suit the

wearer.

The Birdsley in brass on a convertible 45 Colt/ACP. Definitely more than

the sum of its parts.

A brass Keith No5 with a Bisley trigger guard.

A Potato Judge JR in brass on a Linebaugh custom 500.

A custom 360 Dan Wesson by Ronnie Wells wearing a BFG Large Grip frame.

|

|

I have watched with more than a little interest the development of Ronnie Wells' grip frames. For as long as I can remember I have wanted a Ruger Bisley grip frame made of aluminum instead of steel. The internet forums made clear that Ruger grip frames made of brass would be a huge hit as well. Sixgunners all over the USA up to now had to swap, modify or otherwise manipulate the Ruger factory offerings to suit their hands for various reasons. Some examples include the grip frame was too short, the trigger guard would whack them on the knuckle from recoil, or they needed something for oversized or undersized hands and fingers.

Enter the genius of Ronnie Wells who has absolutely crushed the Ruger factory single action grip frame woes. His machine shop magic has to be seen to be believed. Let me see if I can get his machine shop skill in proper perspective using an analogy. If you asked Ronnie Wells what time it was, Ronnie could not only tell you what time it was but how the atomic clock was built. He uses sophisticated software to map out the tool paths needed to machine via CNC his grip frames. These are a far cry from the cast grip frames we have seen before. These are clearly the best quality grip frames ever produced. The fit and finish are as beautiful inside as they are outside. No need to "deck" these frames for custom grips. No need to make modifications for large or small hands as these features are all built in. And yes, they bolt up perfectly to any Ruger revolver mainframe. I drove up to Houston to meet Ronnie Wells and visit his shop. The space age software he uses was not unlike Tony Stark as Iron Man in his lab. Ronnie can call up a grip frame schematic and twist it and turn it in any direction he needs to be sure all is perfect. The Ruger Single Actions use common screw locations in front and behind the trigger guard as well as the rear of the ears of the mainframe. The day I visited Ronnie Wells he had 243 grip frame combos and was open to more variations. These encompass not only the New Models but the Old Model Rugers as well. More, Ronnie Wells has made sure he has covered all the bases. For example, the aluminum grip frame Bisley model I fit to my Blackhawk was very proud on either side of the main frame rails. This was no accident. Ronnie built it that way so it would also fit the longer framed Ruger Maximums! A mid grip frame pin hole is built in to provide extra strength for grips on the hard kickers. This feature allows you to omit the forward grip frame pin hole for slimmer grips for smaller hands. You can also order your grip frame to use the OM style trigger return spring and plunger or the NM style spring arrangement.

Aside from the common screw locations of the Ruger mainframes, Ronnie Wells maintains the integrity of his designs by utilizing two locator holes. These are common to his grip frames and are the reason he can move the backstrap and front strap forward or backward to suit. He can also shorten or lengthen his grip frames while making sure there is sufficient material in critical areas. For example where the front strap is moved away from the trigger guard to provide more "knuckle" room there is plenty of meat behind the front strap to insure more than adequate strength.

You owe it to yourself to call Ronnie Wells to order your grip frame. He is not only a fountain of sixgun knowledge but he is also an absolute hoot to talk to! He has developed his own Sixgun Lingo and applies it to his products. One of our mutual friends and fellow sixgun men is a man who uses the handle "Potato Judge". We know him as Dr. B and he is one of the most respected men in the sixgun community. Dr. B campaigned for a round butt on his Bisley grip frames so Potato Judge is used to designate Ronnie's round butt Bisley grip frame. A Potato Judge JR is scaled for smaller hands. A Potato Judge Youth would then be for little ones. If your favorite lady has really small hands the "PJY" would be the correct option.

Ronnie Wells has not only really done his homework but has also sought out and consulted with some of the most well known shooters and gunsmiths in the USA. For example David Bradshaw of Silhouette fame needed a grip frame set up for longer fingers. So if you have extra long fingers The Bradshaw Bisley has a backstrap that is moved 3/16's to the rear. Ronnie Wells also makes a version with the toe cut for better control with your little finger. David Bradshaw feels this feature is an aid in follow through for better control throughout the recoil signature. David also feels the Ronnie Wells grip frames are so well thought out so as to prevent injury to your hands they could well extend your sixgunning years. Bradshaw further notes that Ronnie Wells takes custom single actions to an individual level that doesn't disturb the original gun.

In his forever quest for better control Ronnie has not only consulted with some hand surgeons he has managed to map out the recoil points of the single action grip frame. Several sessions with a High speed camera to watch the recoil effects after changes in geometry to the grip frame have proven to be very valuable in his quest for better control and preservation of the many small bones in your hands. Here he took his education in anatomy and applied it to how the single action grip frame recoils in your hand. High pressure loads and the effects of heavy bullets are just two of the factors taken into consideration. Ronnie observed the difference in grip angle between the Super Blackhawk and Bisley grip frames is some 8 degrees. By moving the Ruger Bisley grip frame back 4 degrees and thereby rotating the web of your hand toward your sixgun a significant gain in leverage is achieved. Ronnie tells me he has gone from being done after 3 cylinders of 500 Linebaugh 525 grain locomotive derailers to being able to shoot two 64 round Case Guards of the big loads without discomfort. This is significant. It is next on my sixgunners list of things I gotta have. Ronnie Wells points out that for 150 years sixgunners have made do with some 6 to 12 different grip frame shapes. He observes "Sixgunners have adapted our hands to those few choices and now it's time to adapt our choices to our hands." Ronnie wants to be able to build that grip frame that is perfectly suited for any individual hand. With over 6 Billion pairs of hands on the planet, each with different fingerprints, how can we expect to find the perfect match with the few choices previously available? The end of the known universe seems to be the limit for Ronnie Wells. He literally has addressed everything the combined sixgun community could think of. Some Sixgunners prefer the Colt 1860 style grip frame. You can get one in brass and take a trip back in time. The combination of the Bisley front strap and Birds Head backstrap make up his Birdsley grip frame. Ronnie further covers all the Birds Heads bases by combining a Keith No5 skeleton to become the K-Bird, the XR3 skeleton to become his X Bird, and the XR3 RED skeleton is called the Red Bird. His Bison Hunter is a lengthened, finger grove Bisley that includes the 4 degree angle for best control and a larger trigger guard for gloved fingers. David Bradshaw has three frames sporting his name, the Bradshaw which is a Ruger Bisley interpretation extended rearward 3/16s of an inch for larger hands and much needed Knuckle clearance for the big Boomers. The BFGS or Bradshaw Finger Groove Standard and the BFG L which designates the Bradshaw Finger Groove Large. Much attention has been given to consistent finger placement on the Bradshaw versions. Ronnie also makes a number of variations of the famed Keith No5 grip. I'm going to cut in here and point out yet another interesting feature of ALL of Ronnie Wells grip frame designs. You have the option to utilize any trigger guard style you like. Additionally, many of the RW grip frames will have a plus .300 designation. This denotes the bottom of the grip frame has been extended by .300 thousandths. So, you can have a brass Keith No5, plus .300 with a standard trigger guard. Or a Wells # 9 which is a Keith # 5 styled frame that is .400 thousandths longer with a bisley Trigger guard. Or a XR-3, plus .300 with a Bisley trigger guard. Don't like the Super Blackhawk style square back trigger guard? No problem. Oh, wait, you happen to be a Dragoon lover? How about an aluminum K-Bird with a Super Blackhawk trigger guard. There is even an XR3 RED plus .300 with a Dragoon Trigger Guard. There is also an option for an oversized trigger guard for gloved hands. These are only a few of the grip frame options. Ronnie Wells grip frames are currently available in brass and aluminum. These start out as a solid block from which 90 percent of the material becomes chips. Each material requires its own CNC machine since these chips are recycled and contamination must be avoided. So, one CNC machine does the aluminum frames and the other CNC machine does the brass frames. Thus far Ronnie Wells has invested in the hundreds of thousands of dollars in this venture and as he recoups his investment we will see stainless steel, carbon steel, and perhaps titanium. Great grip frames require great stocks. Ronnie has grips available that fit so perfectly you have to see it to believe it. Think "submarine hatch tight" inletting. Materials run from the best Micarta available to the finest walnut you can locate and more. These come already perfectly inletted and ready for shaping and finishing. Complete with escutcheons and screws. I particularly like his palm swell grips. Stabilized wood is also an option.

Cost is $300 for aluminum and $350 for brass. This price includes all the above custom features and many additional options you can find on

www.rwgripframes.com. Be sure to allow yourself some time to study his website because I guarantee you the array of options is literally mind boggling. In a time where our finest sixgunsmiths charge 100 plus dollars per hour for their work you are better off buying a RW

Grip frame unit that already encompasses your personal needs than having a cast factory unit brought up to this kind of quality, fit, and finish. In fact, many of our best sixgunsmiths have already discovered and are taking advantage of the quality these grip frames bring to their custom sixguns. Lest these scribbles become a book, let me close by saying Ronnie Wells is indeed a Game Changer. Because there is more to come. You see, the only way to make all these grip frames better is to offer top quality hammer and trigger combinations to personally suit your project. This will require a follow up article. I guess I better get to work!

RW

Grip Frames: www.rwgripframes-com.3dcartstores.com/.

Fermin

Garza

Got something to say about this article?

Want to agree (or disagree) with it? Click the following link to

go to the GUNBlast Feedback Page.

|

|

Click pictures for a larger version.

.jpg)

Long-Cylinder Old Model Blackhawk 44 Magnum with Ronnie

Wells Brass Bisley grip frame, built by Ross

Custom Arms, operated by Ryan Ross.

RW Grip frames are available precisely inletted with

fine wood.

A custom Ruger fitted with an aluminum PJ grip frame by Matt Grabbe at Tyler

Gun Works.

Note the flawless inletting and shaping of the wood on this PJ grip frame in

brass. Displayed here by our own Dr. B.

A brass Bisley by Tyler Gun Works.

The famous Ruger No3 made up special for David Bradshaw by Bill Ruger answers

the question as to how will brass look on a stainless sixgun.

The BFG Large with extra large trigger guard shown here in Ronnie's Bear

sized paw.

A matte 45 Colt in stainless by Dave

Clements fitted with a brass PJ grip frame.

A brass XR3-RED plus 300 on a custom by Lee Martin. This unit brings another

level of control over the original design.

The brass Bradshaw Bisley weighs 11.8 ounces. One half pound more than its

aluminum counterpart.

|

![]()