|

Revolver accuracy can sometimes be a source of

constant aggravation (see Jeff's earlier writing on this

subject at Revolver Accuracy). Shooters experiment with various loads and

bullet designs trying to achieve groups that donít resemble

buckshot from a skeet gun. Some revolvers exhibit good accuracy

with little or no effort at all, while others of seemingly the

same quality will not shoot a decent group no matter the amount

of work and frustration involved. There are many variables in

getting a revolver to shoot accurately, and most gun makers do a

good job, at least on their hunting guns. With everything that

the bullet must endure before leaving the muzzle of a revolver,

it is sometimes amazing that they can place a bullet close to

the intended target. In this article, I will not attempt to

address every element of revolver accuracy, but one particular,

and crucial variable: the cylinder throats.

The cylinder throat on a revolver plays an

important part in revolver accuracy in a couple of ways. The job

of the cylinder throat is to guide the bullet from the cartridge

case into the throat of the barrel. Assuming that the barrel and

cylinder are properly aligned, the transition from cartridge

case to the rifling of the barrel should be a smooth one, with

any slight misalignment corrected by the forcing cone of the

barrel.

Problems occur that are detrimental to accuracy

when the cylinder throats are not sized properly in relation to

the groove diameter of the barrel. The cylinder throats should

be the same as, or slightly over, the groove diameter. When a

throat is too large, the bullet will be "bumped up"

upon firing to fill the throat and then squeezed back down upon

entering the bore. In my experience, this is not much of a

problem with modern guns. The opposite of this condition is when

the cylinder throats are undersized, or smaller than the groove

diameter of the barrel. In this situation, the bullet is

squeezed down upon entering the cylinder throat and then bumped

up when entering the barrel to fill the groove diameter. The

problem occurs when the bullet, which is now undersize for the

barrel, does not bump up to proper diameter. This happens with

both hard cast bullets and jacketed bullets, leaving a bullet

traveling down the bore without a good seal or proper rifling

engagement, resulting in excessive bore leading and imperfect

alignment upon leaving the muzzle, and the result at the target

is poor accuracy.

It would seem that after over 150 years of

revolver manufacture, that those involved in the process would

have settled upon a proper diameter for cylinder throats in

relation to barrel dimensions, but it just ainít so. Oddly,

the problem occurs most often with our oldest centerfire

revolver cartridge in common use; the .45 Colt. This cartridge

has been with us for almost 130 years, and still guns are being

shipped daily with undersize cylinder throats. I have also

observed this condition on new revolvers chambered for the .32

Magnum cartridge. I have several sixguns chambered for the .44

Magnum and Special, the .38 Special, and the .357 Magnum, all

with properly sized cylinder throats. I have a few older .45

Blackhawks that have perfectly sized throats. I also have some

newer .45 Rugers that have cylinder throats that are too small.

I have a pair of .45 Ruger Vaqueros that were shipped with a

proper bore diameter of .452, with cylinder throat diameters of

between .4505 to .451. I like to shoot the excellent Cast

Performance gas-checked bullets (see Jeff's article at Cast Performance)

in all of my revolvers for their

superb quality, power, and accuracy, but in these two Vaqueros

not even these fine bullets would shoot accurately.

Brownells gunsmith supply sells a tool to

correct the problem of undersize cylinder throats on .45 caliber

revolvers. The tool consists of a throat reamer that will open

the throats up to .4525, and a pilot bushing to insure proper

alignment of the reamer. They also sell a pack of five assorted

pilot bushings to allow for perfect alignment in throats of

various sizes. The only other item needed, is a T-handle to turn

the reamer, such as is used to turn a threaded tap.

For purposes of this article, I started with the

aforementioned pair of .45 Vaqueros. These two revolvers are,

except for serial number, identical. They were built about a

year apart, but dimensions in barrels and cylinders are the

same. Both guns were fired at a range of 25 yards with several

different loads, varying from light plinking loads, to heavy

hunting loads, with cast and jacketed bullets of semi-wadcutter,

roundnose, flatnose, and hollow point design. One thing that

these two revolvers shared was consistency. All loads tested

grouped between three and one-half to four inches, regardless of

bullet design or velocity. Point-of-impact varied with bullet

weight and velocity, but accuracy was very consistent. It really

sucked.

After the initial accuracy tests, the cylinders

were removed from both guns, and the throats were reamed as per

the instructions provided. The procedure is very simple, and all

work is done easily by hand. It basically involves fitting the

pilot bushing to the cylinder throat, oiling the tool, and

turning the T-handle. Both cylinders were reamed, cleaned and

back in the two Vaqueros within 35 minutes. The guns were then

again fired for accuracy using the same loads as previously

fired. The results were amazing. With plinking loads, the

accuracy was improved by about one and one-half inches at 25

yards, grouping into about two and one-half to two and

three-quarters inches.

With the heavier bullets, such as the Cast

Performance 335 grain gas check and the Hornady 300 grain JHP,

accuracy was greatly improved in both revolvers. The guns were

still very consistent, but accuracy no longer sucked. Both

revolvers now shoot into one and three-quarters inches at 25

yards, and that is with the fixed Vaquero standard sights. That

is as good as I can shoot this type of sight. These two Vaqueros

were transformed from a couple of great plinking revolvers into

a pair of accurate sixguns for hunting or serious shooting.

They are light, handy, and powerful, with the accuracy to

reach distant targets with confidence. They are now what they

should have been all along. Iím not picking on Ruger here, as

they are not alone in this problem, and are building these guns

as they think best, but in my experience, the throat diameters

need to be increased.

There are untold thousands of good .45 revolvers

that could benefit from this simple procedure, with more being

made every day. If you have a .45 Colt, .45 ACP, or .45 Auto Rim

revolver, shoot it first. If it is accurate, you are blessed. If

it is not, the problem could be undersize cylinder throats, and

Brownells has the answer. The reamer with the extra pilot

bushings costs about a hundred bucks, but will do many cylinders

and last forever if used properly. The reamer with only the .448

bushing is $65, but I highly recommend the extra bushings. You

can find Brownells on the web at: www.brownells.com

or call them at: 641-623-4000. The part number is

513-000-001 for the reamer, and 513-000-002 for the extra pilot

bushings.

Jeff Quinn

Ed. Note: these reamers are available for the

same price direct from the manufacturer at:

Dave Manson Precision Reamers

8200 Embury Road

Grand Blanc, MI 48439

1-810-953-0732

Boge Quinn

Got something to say about this article? Want to agree (or

disagree) with it? Click the following link to go to the GUNBlast Feedback Page.

|

|

Click pictures for a larger version

Brownells' cylinder throat reaming tool is a simple and

relatively-inexpensive way to solve a common accuracy problem

with .45 revolvers: undersize cylinder throats. As tested, the

reamer kit consists of the cutting tool and six pilot

bushings. A T-handle, commonly seen in tap sets, and oil are

the only other items needed.

The reamer tool is easy to use, even for the

inexperienced pistolero.

Guns tested for this article were two identical Ruger

Vaquero .45s. Prior to testing of the Brownells tool, these

two sixguns exhibited great beauty, exceptional handling

qualities, and terrible accuracy.

Test loads included some of the author's favorite .45

Colt loads, including the great Cast Performance 335-grain gas

checked bullet (3rd from left). These loads have proven to be

very accurate in guns with properly-sized cylinder throats.

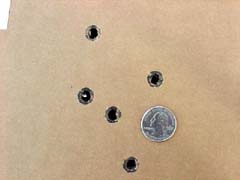

Prior to testing of the Brownells tool, "Gun

#1" (shown at left above) was slightly more accurate (or

less inaccurate) than "Gun #2". Gun #1 consistently

sprayed groups of about 3-1/2" with any

reasonably-accurate load.

Gun #2 was also consistently inaccurate prior to testing

of the Brownells tool, producing patterns (one hesitates to

call them "groups") of about 3-3/4".

Author bench-testing the test Vaqueros. Jeff's lack of

patience with inaccurate revolvers is well-known, and led him

to test the Brownells cylinder throat reamer.

Author found the Brownells tool very easy and intuitive

to use. Both Vaqueros were completed and reassembled in less

than 35 minutes.

Results were amazing, with both guns now capable of

consistent accuracy of 1-3/4" at 25 yards, which is as

well as the author can shoot with the rudimentary Vaquero

sights. For less than a hundred bucks, this tool is a great

solution for a common problem with modern .45s and will last

forever given proper care. Jeff considers the Brownells

cylinder throat reaming tool a necessity for the serious .45

shooter.

|

![]()